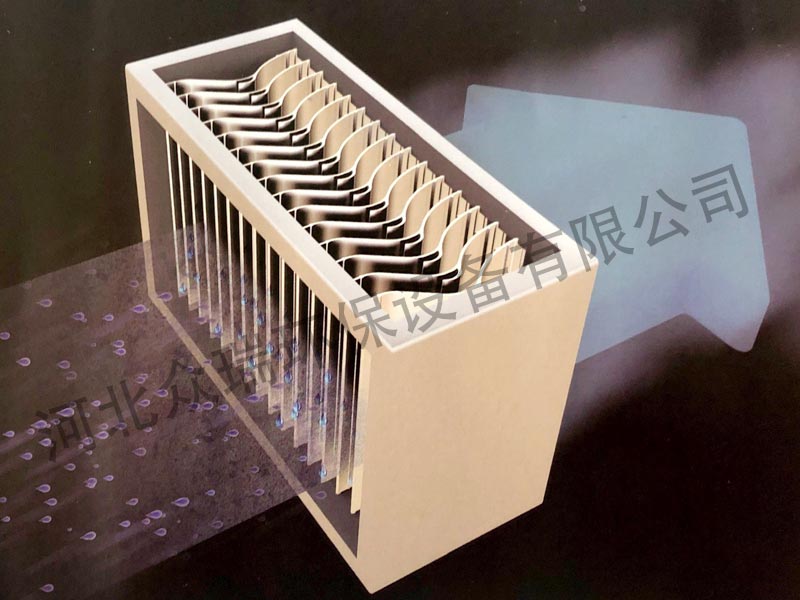

The main components of the mist eliminator include wavy flakes, rigid sheets and clip strips. A lot of fine mist can appear in desulfurization and other technologies, but there are a lot of water molecules, potassium sulfate, sulfur dioxide and many other chemicals in these mists, which will cause blowers, exhaust pipes and heat. Due to the destruction and erosion of machinery and equipment, such as desulfurization, attention should be paid to the defogging function of machinery and equipment when desulfurization is completed. The gas that needs to be discharged must be removed from mist. The mist removal nozzle needs very powerful function and also has a long service life, so the nozzle is made of very good plastic.

If some industrial production masters with desulfurization experience, they will prepare such a mist eliminator in the early stage of industrial production. After all, with the help of such a machine, there is no need to worry about the production environment containing these mists. It is affected, and although this type of machine is very expensive in terms of price, these workers still recommend buying it, because this can prevent large machines from being damaged by these droplets. In fact, these water mists look like some simple The water vapor is almost the same, but the composition of the water mist in the industry is not so simple. Generally, it contains a lot of corrosive substances, and there are also many substances with high adhesion. Therefore, if the water mist exists in the absorption tower Inside, it is natural that such production work cannot be carried out without being affected.

Generally speaking, the demister system is mainly composed of flushing nozzles, flushing pumps, valves, pressure instruments, pipelines and other control parts. It is usually used for flue gas desulfurization and flue gas demisting in steel plants. It is widely used in the products of manufacturers.

The demister flushing system can prevent blade fouling and clogging, and maintain the normal operation of the system. In many cases, single-sided flushing cannot clean the surface of the defogger blades. Therefore, processing must be performed under specific conditions. Single-sided flushing can be used on the defogger, but there are more or less hidden dangers.

We know that when some mist eliminators exist in the suction tower, we will not worry about the various machines and components in the suction tower being corrupted by these corrosive droplets, and we will not worry that these droplets will adhere to The surface of the tower caused the blockage of the flue, probably due to the corrosion of the fan, etc. I really thought about this dull effect, even if it is more expensive, it can be understood. After all, its use is indispensable, only Relying on this kind of rigidity to remove some of the water mist in the production environment, it is possible to protect the rigidity of the workshop from being damaged. If the rigidity can operate normally, some products can be produced. Therefore, the normality of the packaging machine is a stressful event. Therefore, this special defogging production equipment can fully play its protective role.

The mist eliminator deals with the protection of some rigid parts. Usually, it covers two aspects. One is that the water mist contains corrosive substances, so if this kind of droplet is released, it can cover the fan. It is the parts that are easily corroded such as heat exchangers, and there will be no destructive environment; the other is that the droplets contain some highly dependent substances, so only these substances that are easy to adhere to the surface of the machine are removed. Only then can the surface of the flue and other components be relatively clean, without the adhesion and influence of some stains, such flue components can smoothly exhaust smoke. Here we recommend the results of stainless steel demisters.

Therefore, in order to avoid hidden dangers, the defogger should be arranged in double-sided flushing as much as possible. The nozzle is an important executive component in the defogger flushing system. Generally, a solid cone nozzle is used. Normally, the nozzle spread is usually set at 75. Within the range of °~90°.

Under normal circumstances, the larger the diffusion angle of the flushing nozzle, the larger the spray coverage area. The smaller the nozzle diffusion angle, the more nozzles are required to cover the entire demister section. This is also what we are using the demister A piece of knowledge to be understood at the time.

The defogging power of the mist eliminator is added with the addition of the airflow speed. This is because the flow rate is high and the inertial force acting on the mist is large, which is beneficial to the separation of gas and liquid. However, the increase of flow rate will form the increase of system resistance and increase the energy consumption. And if the flow rate is added, if the flow rate is too high, secondary water will be formed, thereby reducing the demisting power.

0317-7666022

0317-7666022

Message

Message